The department of Mechanical Engineering has come into existence, since the inception of the college, in the year 1985. The Present intake of students for B.Tech program is 120 and 12 for M. Tech. program in Advanced Manufacturing Technology. The Department is fortified with 26 teaching faculty and 10 supporting staff. 16 of the faculty members possess Ph. D. degrees; 9 faculty members are pursuing their Ph. D. degrees, and the rest of the faculty members are with M. E./ M. Tech. degrees.

The department is equipped with twelve well established labs that give hands on practical knowledge in the subjects. The department also runs PLM- Excellent centre that trains the final year B. tech. students in PLM software. A research lab on Composites testing is established to promote research in that area. APSSDC has sanctioned Siemens skill development center under which, CNC center and Manufacturing welding labs were established, in which, students from Polytechnics and Vocational courses are trained. Relevant licensed softwares like PLM, MAT Lab, Design Expert, Auto CAD, ANSYS Work Bench, CATIA R12, Uni-Graphics NX2.0, Solid Edge V14, CADian, Mechanical Desktop, Inventor-6, Esprit CAM, and Master CAM have been catering to the needs of students and faculty.

VISION

To develop the department into a model center of education and research in the field of Mechanical Engineering and allied areas and to become a significant contributor to the development of industry and society.

MISSION

M1 To impart quality technical education in emerging fields of Mechanical Engineering through balanced academic curriculum in accordance with changing industry requirements.

M2 To establish centers of excellence where students can strengthen their entrepreneurial skills, technical workmanship, and research proficiency.

M3 To provide opportunities/platforms for students to nurture leadership abilities, ethical values; and to enable them learn responsibility and accountability at work.

Programme Educational Objectives (PEOs)

The educational objectives of the under-graduate programme in Mechanical Engineering at G. Pulla Reddy Engineering (Autonomous) Kurnool are to prepare graduates to possess the ability

PEO1. to apply a broad, fundamental-based knowledge, and up-to-date skills required in performing professional work in Mechanical Engineering and related disciplines.

PEO2. to design works pertaining to Mechanical Engineering, incorporating the use of design standards, realistic constraints and consideration of the economic, environmental, and social impact of the design.

PEO3. to use modern computer software tools to solve Mechanical Engineering problems and explain and defend their solutions and communicate effectively using graphic, verbal and written techniques to all audiences and

PEO4. to become successful entrepreneur or leaders in private/governmental organizations or enter graduate programs in Mechanical Engineering and related disciplines and to pursue lifelong learning and research.

Programme Outcomes (POs)

Mechanical Engineering Program Students will be able to

1. Engineering knowledge: Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems.

2. Problem analysis: Identify, formulate, review research literature, and analyze complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences.

3. Design/development of solutions: Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations.

4. Conduct investigations of complex problems: Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions.

5. Modern tool usage: Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modeling to complex engineering activities with an understanding of the limitations.

6. The engineer and society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

7. Environment and sustainability: Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable development.

8. Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice.

9. Individual and team work: Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings.

10. Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

11. Project management and finance: Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

12. Life-long learning: Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change.

Program Specific Outcomes (PSOs)

Mechanical Engineering Program Students will be able to

PSO1. Understand the concepts of basic Mechanical Engineering and apply their theoretical & practical knowledge to solve problems in Thermal Engineering, Machine Design, Production Engineering and Industrial Engineering.

PSO2. Solve engineering design and manufacturing problems, using CAD, CAE, and CAM tools, along with analytical skills to arrive at the better solutions.

PROGRAM : B.Tech(Mechanical Engineering)

INTAKE : 120

PROGRAM : M.Tech (Advanced Manufacturing Technology)

INTAKE : 12

Program : FULL TIME Ph.D

Faculty Profiles

|

|

|

|

|

|

|

|

|

/strong>

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Guest Faculty

|

|

Board of Studies

| Sl.No. | External Member | Internal Member |

| 1 | Dr. M. Ramji Professor Department of Mech. and Aerospace Engg. IIT Hyderabad, Kandi-502285, Sanga Reddy, Telangana Cell: 9490193175 Email: ramji_mano@iith.ac.in Nominated by JNTUA |

Dr. K. Madhava Reddy Head of ME & Chairman, BOS G.P.R. Engineering College Kurnool |

| 2 | Dr. G. Amba Prasad Professor of Mechanical Engineering NIT, Warangal, Telangana-506004 Cell: 8332969315 Mail: gap@nitw.ac.in Nominated by Academic Council |

Dr. Y. Venkata Mohan Reddy Professor of Mech. Engg. G.P.R. Engineering College Kurnool |

| 3 | Dr. J. Krishnaiah Associate Professor of Mechanical Engineering IIITDM, Jagnnathagattu Hill, Kurnool-518008, Andhra Pradesh Cell: 9442544782 Mail: krishnaiah@iiitk.ac.in Nominated by Academic Council |

Dr. V. Satish Kumar Professor of Mech. Engg. G.P.R. Engineering College Kurnool |

| 4 | Dr. N. Kishore Nath Scientist-G Project Director – VEDA Advanced Systems Laboratory, DRDO, Hyderabad, India Cell: 9490774246 Mail: lca_droptank@yahoo.com Representative from Industry |

Dr. E. Venugopal Goud Professor of Mech. Engg. G.P.R. Engineering College Kurnool |

| 5 | Dr. D. Chakradhar Associate Professor Dept. of Mechanical Engineering IIT Palakkad, Palakkad-678023, Kerala Cell: 9945840896 Mail: chakradhar@iitpkd.ac.in Alumnus, GPREC |

Dr. R. Meenakshi Reddy Associate Professor of Mech Engg. G.P.R. Engineering College KurnoolDr. K. Devaki Devi Associate Professor of Mech Engg. G.P.R. Engineering College Kurnool |

- Department Board of Studies Minutes: ME -BOS-Minutes – 2017-2024

PROGRAM : B.Tech(Mechanical Engineering)

SYLLABUS FOR I B.Tech : Scheme-2010 Scheme-2013 Scheme-2017(Common for All Branches) Scheme-2020 Scheme-2023

SYLLABUS FOR II, III, IV B.Tech : Scheme-2010 Scheme-2013 Scheme-2017 Scheme-2020

SYLLABUS FOR II B.Tech : Scheme-2023

SYLLABUS FOR III B.Tech : Scheme-2023

MOOCs as equivalent for MLC and Global Elective : Scheme-2013

MINOR DEGREE

SYLLABUS FOR MINOR DEGREE IN ME ( Non ME Students) : Scheme-2020

SYLLABUS FOR MINOR DEGREE IN ME ( Non ME Students) : Scheme-2023(3D Printing) && Scheme-2023(Industrial Engineering)

Minor And Honors Programmes Equivalent Moocs Courses: Scheme-2020

HONORS DEGREE

SYLLABUS FOR HONORS DEGREE IN MEC : Scheme-2020 Scheme-2023

PROGRAM : M.Tech (Advanced Manufacturing Technology)

SYLLABUS FOR M.Tech (Advanced Manufacturing Technology): Scheme-2022

ACADEMIC REGULATIONS FOR UG (B.Tech): Scheme-2010 Scheme-2013 Scheme-2017 Scheme-2020 (Revised) Scheme-2023-Regulations(with-amendments-as-directed-by-JNTUA)

ACADEMIC REGULATIONS FOR PG (M.Tech): Scheme-2013 Scheme-2017 Scheme-2022

Student Activities:

Student Achievements (2022–2023)

- Sreedhar Naidu received the Best Mechanical Engineering Student award at ISTE organized by ISTE Andhra Pradesh Section in 2022.

- Karthik Vineel Kumar secured First Prize in Smart India Hackathon held at D.Y. Patil College of Engineering, Pune on August 25–26, 2022.

- Phani Bushan secured First Prize in Yantra 2K22 organized by JNTU, Pulivendula on 29–30 September 2022.

Student Achievements (2023–2024)

- Rakesh Reddy secured II Prize in the National Level Technical Symposium conducted by MITS, Andhra Pradesh on 01-05-2024.

- Dinesh Kumar secured I Prize in the Technical Quiz at the National Level Technical Symposium organized by SV University, Tirupati on 20-03-2024.

- Sagar secured II Position in the All India Inter University South Zone Tournament held at Hindustan University, Chennai from 07-01-2024 to 16-01-2024.

- Rajasekhar secured I Position in the All India Inter University South Zone Tournament conducted at the University of Calicut, Calicut from 26-12-2023 to 30-12-2023.

- Bhavani Prasad secured I Position in the All India Inter University South Zone Tournament organized by Bharathidasan University, Tiruchirappalli from 24-12-2023 to 30-12-2023.

- Sumanth Raj secured I Position in the All India Inter University South Zone Tournament held at VTU, Belagavi from 22-12-2023 to 25-12-2023.

- Uday Kiran received the Best Mechanical Engineering Student award under Student State Awards 2023 organized by ISTE, AP Section (GATES Institute of Technology State Award) for the Academic Year 2023–2024.

- Rajasekhar – Received Cash Prize for Outstanding Performance in Kho-Kho, GPREC (AY 2023–24).

- Bhavani Prasad – Received Cash Prize for Outstanding Performance in Hockey, GPREC (AY 2023–24).

- Sagar – Honored with Chinta Memorial Cash Award for Outstanding Performance in Cricket, GPREC (AY 2023–24).

Student Achievements (2024–2025)

- Bhavani Prasad– Achieved II Position at All India Inter-University South Zone Tournament, University of Madras, Chennai (31-01-2025 to 07-01-2025).

- Rajasekhar– Secured I Position at All India Inter-University South Zone Tournament, Central University of Tamil Nadu, Thiruvarur (27-12-2024 to 31-12-2024).

- Sai Charan– Won 1st Prize in Tecrity, JNTUA College of Engineering (29-10-2024).

- Karthik Reddy– Won 1st Prize in Tecrity, JNTUA College of Engineering (29-10-2024).

- Around 131 MOOC’s courses have been completed by the Students during 2020-2021.

- Mock interviews are conducted to the final year students for the improvement of the student performance.

- Students have been actively participated in the Two day Online WEBINAR organised by the Department of Mechanical Engineering with an association of Capricot Technologies Pvt. Ltd., on “MATLAB for Mechanical Engineers” on 14th and 15th of July 2021 in G. Pulla Reddy engineering college (Autonomous) Kurnool.

- Students have been actively participated in the Online WEBINAR organised by the Department of Mechanical Engineering on Employable Skill sets required in Core Mechanical Industries on 26th May 2021 by G.Ajitha Prabu, Director of Kriatec Services Pvt. Ltd., .

- Students have been actively participated in the Online WEBINAR organised by the Department of Mechanical Engineering on Foundation of PLM (Product Lifecycle Management) on 9th May 2021.

- Students have been actively participated in the Online WEBINAR organised by the Department of Mechanical Engineering on Awareness on Preparation for GATE-2022 on 26th April 2021.

- Students have been actively participated in the THREE DAY Online WEBINAR organised by the Department of Mechanical Engineering on Product Data Management on 18th April 2021.

- Students have been actively participated in the THREE DAY Online WEBINAR organised by the Department of Mechanical Engineering on Product Lifecycle Management from27th to 29th June 2020 through online.

- Around 200 students had participated in two day workshop ROBOTICA -2020was organised by IEEE Robotics and Automation Society (RAS) SB in association with Department of Mechanical Engineering on 7th & 8th of March 2020 in GPREC, Kurnool. Under ROBOTICA 2020 two topics are covered , one is “HUMANOID” and other is “IOT WITH CLOUD ROBOTICS”.

- Around 10 Students of VI Semester had participated in the IEEE AHCSSC 2020with the theme Digital Reality, AI and Robotics held at Anurag Group of Institutions, Hyderabad during 3rd to 4th January 2020.

- A total of 64 Students of VI Semester had attendedTwo day workshop on Applications with MATLAB-2019b held at GPREC Kurnool during 27th and 28th December 2019.

- A total of 43 Students had undergone a training program on CNC Turning (Foundation Level)in association with A.P.S.S.D.C. at GPREC during 30th September 2019 to 05th October 2019.

- Around 40 Students had attended Twoday workshop on 3D Printing at IIITDM Kurnool, during 28th to 29th September 2019.

- Seminars, Quiz competitions, CAD competitions, Essay writing, Poster presentation activities are conducted under IE(I) Mechanical Engineering chapter.

- Students have got exposure on current techniques being used in the Industries by participating in two day workshop on Non-Destructive Testing and Evaluationin association with Acoustics NDT Services, during 21-22 December, 2018.

- Total of 31 students and 30 students of V Semester have participated in one week workshops on CNC Programming and on ROBCADrespectively, organized by APSSDC from 29 July, 2019 to 3 August, 2019.

- One day workshop on ROBOTICS and 3D Printingwas organized by IEEE Robotics and Automation Society on 27 July, 2019 and students of fifth semester have participated in it.

- Many students have participated in the Blood donation camp organized on 26 July, 2019.

- Many students presented papers in conferences organized by reputed institutes like IITs and deemed to be universities.

Details of Laboratories:

1. Thermal Engineering Lab

This lab provides knowledge on components of IC Engine, Applying Various Loads on 5 HP Diesel Engine, Mechanical Loading on 5Hp Diesel engine, Multi point fuel injection system, Wind Mill, Reciprocating Compressor.

2. Workshop

The Engineering Workshop Laboratory consists of the Carpentry, Fitting House wiring, Soldering, Foundry and Black Smithy sections. First year B.Tech Students of the college perform Experiments in the all sections. The Engineering Workshop Laboratory is also used for fabrication of projects by the students for their Mini Project/Major Projects.

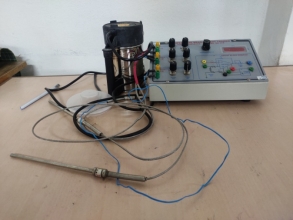

3. Dynamics & Instrumentation Lab

In this lab the students will be able to balance the rotating masses in different planes, verify the magnitude of gyroscopic couple, measure the critical speed of the shaft with fixed end conditions, Measure vibration characteristics of spring mass system, rotor system and damped system, find natural frequency and also able to select proper measuring instrument and know requirement of calibration, errors in measurement, measure pressure, displacement and temperature using instrumentation tutors.

4. CAD Lab

This lab is used to get students familiarize with various 3D CAD software like AutoCad 2015, CATIA V4 R14 and CREO 2.0.

5. CAE Lab

Here in this lab students get familiarize with CAE software namely ANSYS 19.2. Students work on APDL and Work Bench platforms.

6. CAM Lab

This lab gives exposure to the students about Manufacturing simulation, CNC part program generation, part programming verification and Physical Model of the part Program, CNC Machine Tools and 3D Printer.

7. Material Science and Metallurgy Lab

This lab facilitates the students to learn how to find Grain Fineness Number for a given sample of sand, to find the shear and Compressive strength for a given sand Mould, to determine Hardenability for a given shaft, to get familiarize with the Microstructure of different materials, to perform Spot and Arc Welding.

8. Machine Tools Lab

This lab is to impart practical exposure on various machine tools used in the industry and to make the student capable of manufacturing components according to given drawings using machine Tools.

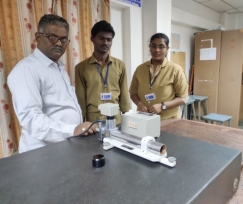

9. Engineering Metrology Lab

This lab offers a practical exposure to students about the usage of relevant instruments for precision measurements required in industry. Available major equipments include Tool Maker’s Microscope, Profile Projector, and Surface Roughness Tester.

10. Heat Transfer Lab

This lab is to provide the practical expose to the students with regard to the determination of amount of heat exchange in various modes of heat transfer.

Some of the Major equipments are shown below:

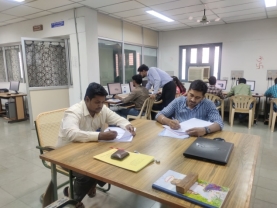

11. Data Base and Computations Lab

This lab is to introduce the students to one Backend application and also to Scientific software tool, Simple Exercises based on ORACLE – SQL*Plus have been included along with few exercises on MATLAB.

12. Seminar Hall

Air-conditioned seminar hall with a minimum of 100 seating capacity is available in department. They are well equipped with Podiums and Projectors. Events such as departmental meetings, seminars/symposia etc., are organized here.

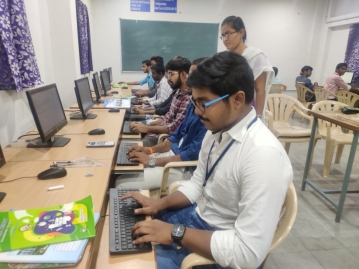

Details of Computer facility in ME Department:

| Number of Computer centers | 2 |

| Number of Computers | 156 |

| Number of Printers | 3 |

| 20 KVA UPS | 2 |

| Number of Computer Servers | 2 |

List of Licensed Software:

| Drafting Software: CADIAN 2002 Auto CAD 2015

Modelling Software: Mechanical Desktop 6 Catia V5 R12 SOLIDEDGE V14 UNIGRAPHICS-NX 2.0 AutoDesk Inventor-6 CREO 2.0 Metallurgical Software Metallurgical Imaging Software Database Software SQL * Plus

|

Analysis Software: ANSYS – R19.2 MSc NASTRAN 2004-R3 MSc ADAMS 2005 ALGOR Multi Physics R4

CAM Software: CREAT BOAT Software for 3D Printing, EDGE CAM Funac – CUTViewer for CNC Programming Design Expert –V10 Decision Tools Suite Espirit CAM Master CAM CNC tutor V.I. Software MATLAB Software |

Department Achievements:

- Department of Mechanical Engineering is accredited by NBA valid till 2022-2023.

- Department is recognised Research Center under JNTUA, Anantapuramu.

- The B. degree in Mechanical Engineering is accredited by the Institution of Engineers (India).

- The ME department has MoUs with the Institution of Mechanical Engineers, Adroitec Engineering solutions Pvt. Ltd.

- Most of the faculty members have published their research works in reputed journals/ presented at conferences. The number of publications in SCI/SCI-E/ESCI journals is 15 and that in Scopus indexed journals is 14 during 2020-21.

- Faculty members have successfully completed NPTEL courses of their interest that are deemed FDPs to upgrade their knowledge.

- Around 80 offers are secured by the students of 2020-2021 in the companies TCS, COGNIZENT, INFOSYS, ACCENTURE, BYHUS, HUNDAI, JAI RAJ ISPAT, DXC.

- Four students have been Qualified in GATE 2021.

- A TWO day Online WEBINAR had been organised by the Department of Mechanical Engineering with an association of Capricot Technologies Pvt. Ltd., on “MATLAB for Mechanical Engineers” on 14th and 15th of July 2021 in G. Pulla Reddy engineering college (Autonomous) Kurnool.

- A FIVE DAY Online WORKSHOP had been organised by the Department of Mechanical Engineering with an association of Kriatec Services Pvt. Ltd., on Advanced SIMULATION of Machining using EDGE CAM from 5th to 10th July 2021 in G. Pulla Reddy engineering college (Autonomous) Kurnool.

- A FIVE DAY WORKSHOP had been organised by the Department of Mechanical Engineering with an association of P.S.S.D.C. on CNC Programming from 21th to 25th June 2021 in G. Pulla Reddy Engineering College (Autonomous) Kurnool.

- A WEBINAR had been organised by Department of Mechanical Engineering on Employable Skill sets required in Core Mechanical Industries on 26th May 2021 by Ajitha Prabu, Director of Kriatec Services Pvt. Ltd., through online in G. Pulla Reddy Engineering College (Autonomous): Kurnool.

- A WEBINAR had been organised by Department of Mechanical Engineering on Foundation of PLM (Product Lifecycle Management) on 9th May 2021 through online in G. Pulla Reddy Engineering College (Autonomous), Kurnool.

- A Online WEBINAR had been organised by Department of Mechanical Engineering on Awareness on Preparation for GATE-2022 on 26th April 2021 through online in G. Pulla Reddy Engineering College (Autonomous), Kurnool.

- A Online WEBINAR was organised by the Department of Mechanical Engineering on Product Data Management on 18th April 2021 through online in G. Pulla Reddy Engineering College (Autonomous), Kurnool.

- A THREE DAY Online WEBINAR was organised by the Department of Mechanical Engineering on Product Lifecycle Management from27th to 29th June 2020 through online in G. Pulla Reddy Engineering College (Autonomous) , Kurnool. Read More…

Faculty Achievements:

- Dr R.meenakshi Reddy received the Best Engineering Teacher Award from Indian Society of Technical Education (ISTE) A.P chapter on Aug 12 2023.

- Dr B sreenivasa Reddy received Best Principal award from JNTUA on 5th September 2022.

- Dr R.meenakshi Reddy received Best Mechanical Engineering Teacher award from ISTE Andhra Pradesh section state Awards- 2021

- Dr R.meenakshi Reddy received best Teacher award from JNTUA on 5th September 2022

- R. Meenakshi Reddy received the National Adroit Teacher – 2021 award from Green ThinkerZ.

- Under the guidence of Y.V.Mohan Reddy One scholar awarded Ph.D from JNTU Anantapur.

- Under the guidence of B.VeeraBhadra Reddy One scholar awarded Ph.D from JNTU Anantapur.

- Under the guidence of R.Meenakshi Reddy two scholars awarded Ph.D from JNTU Anantapur.

- B.Madhusudhan Reddy received the Ph.D in Mechanical Engineering from JNTU Anantapur.

- R.Meenakshi Reddy had published a patent on “Drink ware Capable Of Storing Thermal Energy For Longer Period “ (202041011191, Publication Date : 12/06/2020).

- A Patent was published by R.Meenakshi Reddy on “Energy efficient Dry Cooling System for Thermal Power Plants” (202141000668, publication date 15/01/2021).

- A Patent was published by R.Meenakshi Reddy on “Fabrication and characterization of LM9 alloy reinforced with coconut shell ash particles”, (202141017688, Publication Date: 23/04/2021).

- R.Meenakshi Reddy had filled the Design Patent on “Duster with chalk holder” and “Phone case with camera protection” and waiting for acceptance. Read More…

Students Achievements:

- B.Sreedhar Naidu of IV year Mechanical Engineering secured ISTE Best Mechanical Engineering Student Award on 12th August 2023.

- Around 80 offers are secured by the students of 2020-2021 in the companies TCS, COGNIZENT, INFOSYS, ACCENTURE, BYHUS, HUNDAI, JAI RAJ ISPAT, DXC.

- Four students have been Qualified in GATE 2021.

- Around 131 MOOC’s courses have been completed by the Students during 2020-2021.

- Students have been actively participated in the Two day Online WEBINAR organised by the Department of Mechanical Engineering with an association of Capricot Technologies Pvt. Ltd., on “MATLAB for Mechanical Engineers” on 14th and 15th of July 2021 in G. Pulla Reddy engineering college (Autonomous) Kurnool.

- Students have been actively participated in the Online WEBINAR organised by the Department of Mechanical Engineering on Employable Skill sets required in Core Mechanical Industries on 26th May 2021 by G.Ajitha Prabu, Director of Kriatec Services Pvt. Ltd., .

- Students have been actively participated in the Online WEBINAR organised by the Department of Mechanical Engineering on Foundation of PLM (Product Lifecycle Management) on 9th May 2021.

- Students have been actively participated in the Online WEBINAR organised by the Department of Mechanical Engineering on Awareness on Preparation for GATE-2022 on 26th April 2021.

- Students have been actively participated in the THREE DAY Online WEBINAR organised by the Department of Mechanical Engineering on Product Data Management on 18th April 2021.

- Students have been actively participated in the THREE DAY Online WEBINAR organised by the Department of Mechanical Engineering on Product Lifecycle Management from27th to 29th June 2020 through online. Read More…

- two students qualified for the Gate in 2024 ,in this one student got All India Rank 96.

Instructional Materials:

- E – Content – Click here

- Lab Manuals – Click here

- Lecture notes – Click here

- Product development – Click here

- Project work reports- Click here

Facculty Profiles :

Facculty Profiles for the Academic Year 2023-24 : Click Here

Facculty Profiles for the Academic Year 2022-23 : Click Here

Facculty Profiles for the Academic Year 2021-22 : Click Here

Facculty Profiles for the Academic Year 2020-21 : Click Here

Placement Details :

Placement Details from 2020 -23 : Click Here

Student Nominal Rolls :

Student Nominal Rolls for the Academic Year 2023-24 (Odd Sem) : Click Here